FILTER CLOTH

A critical role to elicit performance of

machines to the fullest

Filters are required by various items for various purposes.

For everyday life, they are used in vacuum cleaners and air conditioners, and for industrial use, in beverage, food, chemical, water treatment, and iron-making facilities.

Filters and our lives are inseparable because they fulfill a critical role in eliciting the best possible performance from machines or devices.

By making full use of our filter cloth manufacturing technology and experience, we would like to satisfy our customers (to put a smile on our customers' faces) by solving their problems.

We offer a thorough and complete service, where we take care of all steps of production, from weaving the fabric to processing it. This enables us to manufacture various kinds of filter cloth for a variety of industries.

“We had no idea that filter cloth could be such a huge improvement to our equipment!”

This is what we often hear from our customers.

Filter cloth is not familiar to ordinary people. We can offer you advice and make suggestions about which filter cloth best suits your needs, based on our vast experience as professionals.

Some customers use unsuitable filters which don't match the specifications of their machines or devices. You might think that this never happens, but it does. As ought to be expected, unless machines and filters are optimally matched, they cannot demonstrate the full extent of their ability.

Don't you find this is a waste of your precious resources?

The life of filters can be easily extended through improvement of quality. The longer the life of a filter, the fewer times you will need to replace it, which leads to better work efficiency.

The more we know about your filter needs in terms of water quality, specifications of your equipment, use conditions, and so on, the better filters we can offer. We can manufacture your own custom-made filters which last the longest, and elicit the best performance from your machines.

Filters are unfamiliar products to ordinary people, so it may be difficult to search for information about them.

We will live up to your expectations.

PRODUCT

There are a great variety of filters. There exist filters which perfectly suit any environment, such as your filter unit, separator, or the quality of the water, depending on where they are used. In this section, we will showcase our inventory of filters for filter units and separators, including our specialty, filters for filter presses.

Other customization options are also available, so please feel free to contact us.

-

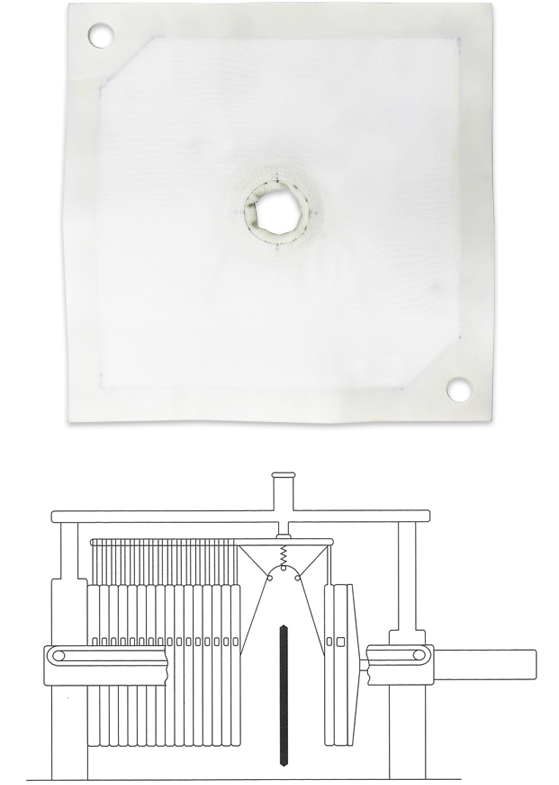

For filter press

Filters for filter presses are the most common and we consider them to be our forte. These are pressurized filters, which are relatively easy to handle and are suitable for use at plants that treat a large amount of wastewater.

While they are easy to handle and use, there are filters which may easily cause problems, such as not matching the specifications of their machines or devices.

-

For centrifugal separators

While filter presses are suitable for a large amount of filtration, the type of filter best suited for a small amount of filtration is the centrifugal. These devices pressurize using centrifugal force or gravity. There are two kinds of centrifugal separators: one is a top-discharge centrifuge, and the other is a top-drive, bottom-discharge centrifuge.

Filters for these devices are used at small-scale factories, as well as ones which deal with special or unique products.

-

For drum vacuum dehydrators

The most distinctive feature of dehydrators is that they are available for continuous operation. Drum vacuum dehydrators are of the pressure reduction type, and are best suited to filtering small quantities of material which contain fine particles.

It is essential to choose and use the filter which is optimally suited for the quality of water you are dealing with. -

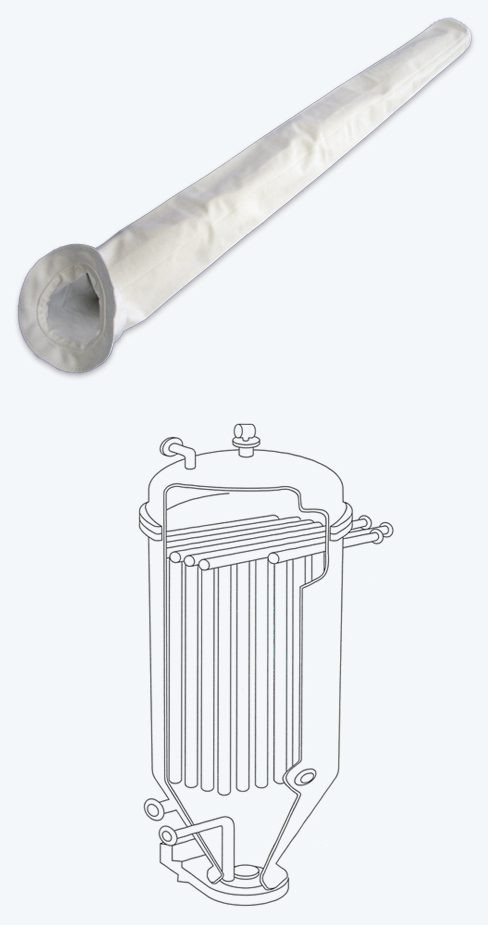

For candle filters

These types of filters are, as the name suggests, in the shape of a candle. They are used in vertical sealed pressure separators. These devices are often installed at assembly lines in chemical plants, or used for desulfurization

About Filter Cloth Materials

Materials Conditions |

Nylon (PA) |

Polypropylene | Tetoron (PE) |

Nomex Nylon | Cotton | Teflon | Glass |

|---|---|---|---|---|---|---|---|

| Heat Resistant Temperature |

120 | 80 | 150 | 170 | 100 | 200 | 270 |

| Acid Resistance |

× | ◎ | ○ | △ | × | ◎ | ○ |

| Alkali Resistance |

○ | ◎ | △ | ○ | × | ◎ | × |

| Wear/Abrasion Resistance |

more resistant  less resistant less resistant |

||||||

◎ = very high, ○ = high, △ = depending on condition, × = not available

The above materials are generally used.

Other materials are also available at your request.

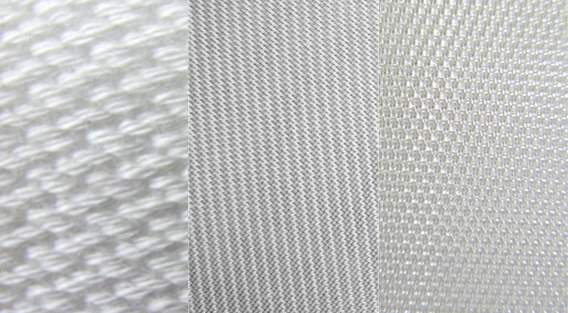

The Type of Yarn and Weave Patterns

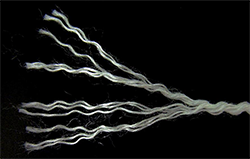

Mono-filament Yarn

Multi-filament Yarn

Span Yarn

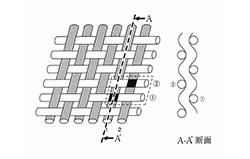

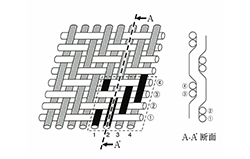

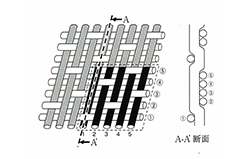

Plain Weave

Twill Weave

Satin Weave

The Characteristics of Yarn and Weave Patterns

Types of Filter Cloth / Filterability |

Ability to Trap Particles |

Filtrate Amount |

Plugging Resistance |

Detachability | Wear Resistance |

|

|---|---|---|---|---|---|---|

| Yarn Design | Span Yarn | ◎ | △ | △ | △ | ◎ |

| Multi-filament Yarn | ○ | ○ | ○ | ○ | ○ | |

| Mono-filament Yarn | △ | ◎ | ◎ | ◎ | △ | |

| Weave Patters | Plain Weave | ◎ | △ | △ | △ | ◎ |

| Twill Weave | ○ | ○ | ○ | ○ | ○ | |

| Satin Weave | △ | ◎ | ◎ | ◎ | △ | |

◎ = very high, ○ = high, △ = depending on condition, × = not available

TECHNOLOGY

Special Technology:

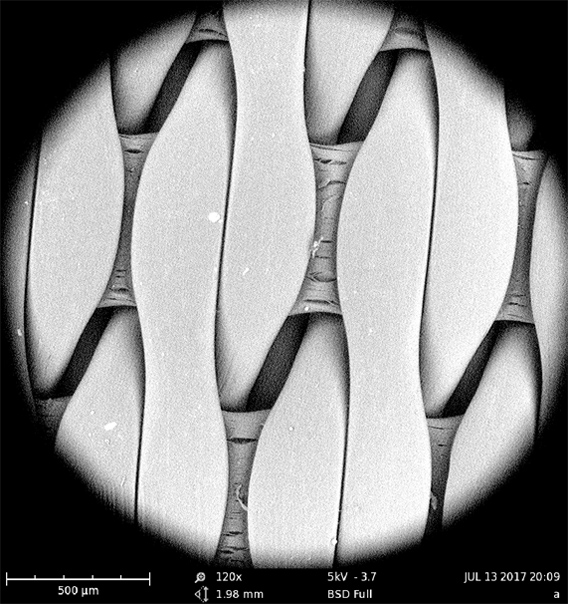

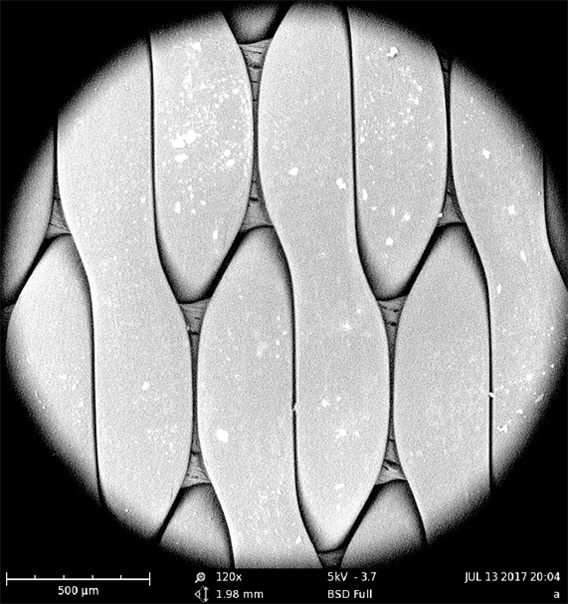

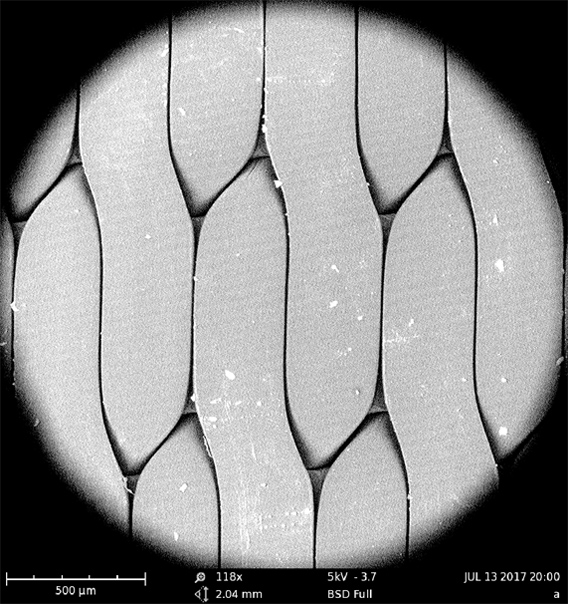

Ohtsuka Calendaring

This technology can process and finalize various kinds of filter cloth by running cloth through huge rollers and adjusting the heat and pressure.

In the fiber industry, priority has been given to speed and mass production.

However, we have always placed great importance on quality, as filters require precision.

Our own policies, experience, and know-how have enabled us to transform even just one kind of cloth into a wide variety of cloths by finalizing it with a previously unimaginable subtle adjustment.

Normally, when we require slightly finer, thinner filters, we have no choice but to start from scratch: selecting yarns, weaving cloth, and making filters. This requires several months, as well as a large shipping order.

However, this technology makes it possible for us to offer you products more quickly, and in much smaller quantities.

photomicrograph of calendared filter cloth

sizing

When processing or finalizing cloth for filter presses or centrifuges, holes are opened up in the cloth by the needle of a sewing machine, which can cause our painstakingly selected filtration cloth to lose its effectiveness and allow particles to escape through.

In order to avoid this, our company, working alongside resin manufacturers, instead co-develops various types of resin, and we apply the resin suitable for your needs and purposes to the filter cloth.

| Type of Resin |

Characteristics | Heat Resistant Temperature |

For food -related use |

|---|---|---|---|

| S | high flexibility/high smoothness/low adhesion | 200℃ | ○ |

| V | high sealing efficiency/high adhesion | 40℃ | ○ |

| H | high adhesion/resin gets firm | 80℃ | ○ |

| M | high endurance/high adhesion/high sealing efficiency | 150℃ | × |

| U | high adhesion | 80℃ | ○ |

| N | high endurance | 120℃ | ○ |

○ = available, × = not available

COMPANY

We manufacture the products entirely by ourselves, from weaving to finalizing the filter cloth, so this enables us to produce filters for various types of industries and trades.

The city of Ashikaga, Tochigi prefecture, is located in an area known as “Higashino Nishijin”.

We are a manufacture that specializes in the full scale manufacture of filter cloth, from weaving to processing the cloth.

We are also able to make proposals based on our extensive experience.

MANAGEMENT

PHILOSOPHY

Our Creed

We will bring happiness and smiles to all people who come in

contact with our company.

So as to accomplish this, we will endeavor, through our enterprise,

to create an inclusive work environment where anyone, including

those with disabilities, can flourish and be successful. We will make

the most use of our skills and experience in order to discover the

true untapped potential of our employees and our business, and

protect the environment and nature.

We will pass this down to posterity.

MESSAGE

Asia Golden Star Award 2017 hosted by AEEF-J

Our company received five awards:

Master Award・Enterprise Award・Entrepreneur Award・Product Award

and Social Contribution Company Award

Asia Golden Star Award 2017 hosted by AEEF-J

COMPANY

PROFILE

- Company Name

- OHTSUKA JITSUGYO Co.,Ltd.

- Date founded

- March 6, 1973

- Capital

- 16 million yen

- Head Office/ Head Factory

- 1745-1 Fukui-cho Ashikaga-shi Tochigi, 326-0338

Tel:+81(0)284-73-1801 / Fax:+81(0)284-73-1907

- Tokyo Branch Office

- Eruhen Building 2-4-8 Kajicho Chiyoda-ku Tokyo 101-0044

Tel:+81(0)3-3252-9831 / Fax:+81(0)3-3252-9833

- Hamamatsu Factory

- 183 Nazukacho Naka-ku Hamamatsu-shi Shizuoka 430-0811

Tel:+81(0)534-61-4593 / Fax : +81(0)534-61-4596

- Osaka Sales Office

- Kurosawa Building 4F 1-10-15 Higashi-Temma Kita-ku Osaka-shi Osaka 530-0044

Tel:+81(0)6-6949-8697 / Fax : +81(0)6-6949-8698

ACCESS MAP

-

- 【Head Office/ Head Factory】

- 1745-1 Fukui-cho Ashikaga-shi Tochigi, 326-0338

Tel:+81(0)284-73-1801 / Fax:+81(0)284-73-1907

- 【Head Office/ Head Factory】

-

- 【Tokyo Branch Office】

- Eruhen Building 2-4-8 Kajicho Chiyoda-ku Tokyo 101-0044

Tel:+81(0)3-3252-9831 / Fax:+81(0)3-3252-9833

- 【Tokyo Branch Office】

-

- 【Osaka Sales Office】

- Kurosawa Building 4F 1-10-15 Higashi-Temma Kita-ku Osaka-shi Osaka 530-0044

Tel:+81(0)6-6949-8697 / Fax : +81(0)6-6949-8698

- 【Osaka Sales Office】